My Sheep2Shawl project began with an Etsy purchase of one pound of raw CVM/Romeldale fleece from an ewe named Ember. Coming from a cold climate (Minnesota) the wool was covered (coated) which helped to keep it free of large amounts of veggie matter (VM) such as hay and field grass. It was beautiful clean fleece.

Ember's lovely locks.

First I chose the individual locks that were similar in color and length. I stacked them carefully so I knew which ends were the tips and which were the cut ends. I'm starting with the lightest colored locks and will progress to the darker wool as I work through the fleece.

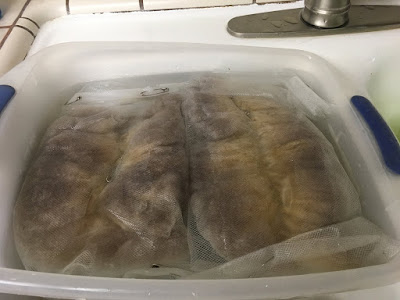

The aligned locks were placed in tulle netting and washed (scoured) with 2 washes and 2 rinses using Unicorn Fiber Power Scour and very hot water. The fleece wasn't too dirty but it was rich with greasy lanolin.

4/25/19, Drying in the sun.

5/2/19, Second batch.

6/28/19, Third batch.

After the locks are thoroughly dried the tips are brushed open (flicked).

Next, the cut ends are placed oh-so-carefully on the metal tines of the Valkyrie Extra Fine mini combs. It took me a few sessions before I felt comfortable with the sharp combs and I keep them covered or lying sideways when I'm not actively combing, especially when my helpers show up.

The combed wool is then pulled through an object with a tiny hole (diz) to make long strips of ready-to-spin fiber.

A light as air "bird nest".

I wanted to spin my prepped fiber as thinly as possible. I didn't think I could do it on my spinning wheel without wasting a lot of it so I learned from YouTube how to spin on a supported spindle.

One bird nest takes me over an hour to spin.

7/4/19, Spun to date:

In the meantime, I'm enjoying every inch, every ounce, every minute of the process.

Happy 4th of July and

Happy Summer Everyone.